Today, the Defense Advanced Research Projects Agency (DARPA) opened up registration for the FANG Challenges, a set of three next-generation military vehicle design competitions that will kick off in January, and will put tools based on approaches borrowed from software development and chip design in the hands of teams of engineers and designers. In an effort to reinvent how such complex systems are designed and built, DARPA is preparing for the first real test of its efforts to use open-source software and Web collaboration—with millions of dollars in prize money at stake.

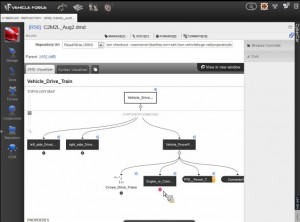

The challenges are the first major milestone in a program that seeks to break the Department of Defense out of the decade-long process that has cost the US hundreds of billions of dollars to produce aircraft, vehicles, and weapons systems that often end up never being built. DARPA's Adaptive Vehicle Make project has funded the development of a set of open-source design tools that allow engineers to use "correct-by-construction" approaches to designing complex systems, using the known characteristics of building-block components from a shared model library to validate a design before it is ever assembled.

Because of the complexity of military systems—or practically any large-scale system—using computer modeling to determine the best possible design from all possible configurations would take "decades of compute time," DARPA AVM Program Manager Army Lt. Col. Nathan Wiedenman said in a press briefing today. But by using the known operating ranges of previously validated components and correct-by-construction techniques, designers can quickly reduce the order of magnitude of the problem, making it easier to verify the overall design.

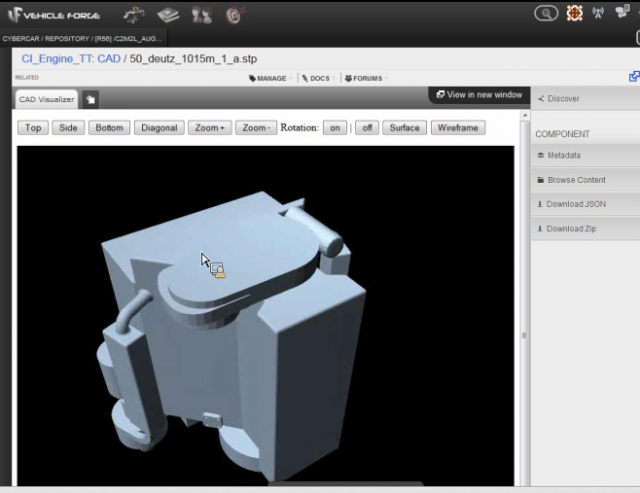

The tools have been integrated into VehicleForge, a Web portal modeled on collaborative software development portals such as SourceForge and GitHub that allows groups of engineers to work together to check in on models and work concurrently on designs. VehicleForge and the FANG design competitions will be open to any US citizen who wishes to participate.

This way, said Wiedenman, the first build of a system "isn't a prototype, it's a production model." And by using the VehicleForge portal to open up the process to a more community-driven approach, Weideman said, DARPA hopes to tap into a broader set of expertise and break out of the locked-in design approaches that have resulted in the spiraling cost of programs like the F-35 fighter, the Joint Tactical Radio System and the Army's ill-fated Future Combat System. Wiedenman said that using a system like VehicleForge for defense systems could shrink the development process down from the current average of 10 years down to as little as two years, saving billions of dollars in the process.

Each of the FANG Challenges is focused on a step in the design and manufacturing of the Fast, Adaptable, Next-Generation Ground Vehicle—an amphibious assault vehicle that meets the requirements of the Marine Corps' long-delayed Amphibious Combat Vehicle program. The winning designs for each step will be manufactured using another part of the AVM program, the IFAB "factory of the future" project —an automated, reconfigurable manufacturing plant that uses computer-numerically-controlled machine tools, 3D-printing and related technologies to turn designs produced through VehicleForge into a final product.

The first challenge, which has a $1 million prize, will be to design FANG's drive train and control systems. The winner of the challenge will be selected based on an evaluation of the design's compliance with the Marine Corps' requirement set, Weideman said. The second challenge, which also carries a $1 million prize, will focus on the chassis and other systems of the vehicle; the final, $2 million challenge, will be for a full build of the vehicle, which DARPA hopes to deliver to the Marine Corps.

Listing image by DARPA

reader comments

16